The Plastic Waste Crisis

Import Dependency

India imports recycled plastic from China at ₹60-80 per kg, creating unnecessary dependency and higher costs for manufacturers.

Environmental Pollution

Massive plastic waste burning causes severe air pollution, while uncontrolled dumping contaminates soil and water sources.

Lost Economic Value

Millions of tons of valuable plastic resources are wasted annually instead of being converted into profitable raw materials.

Inefficient Collection

Lack of organized collection systems leads to waste accumulation in communities, creating health and environmental hazards.

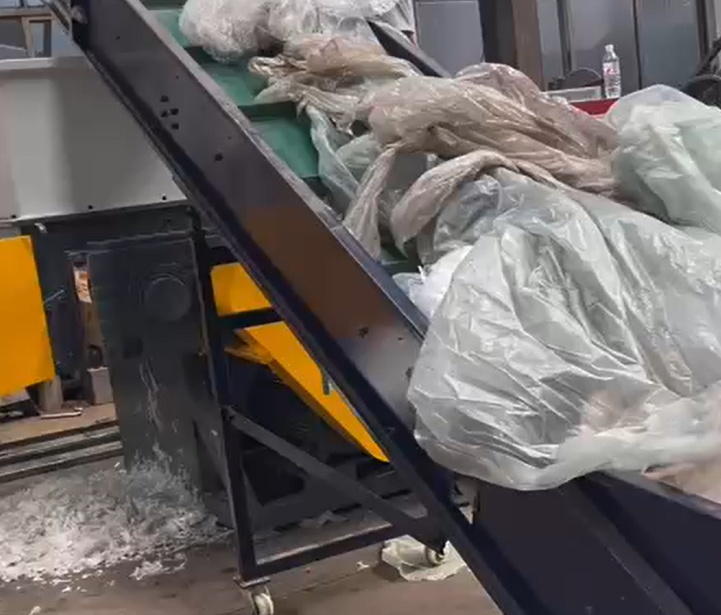

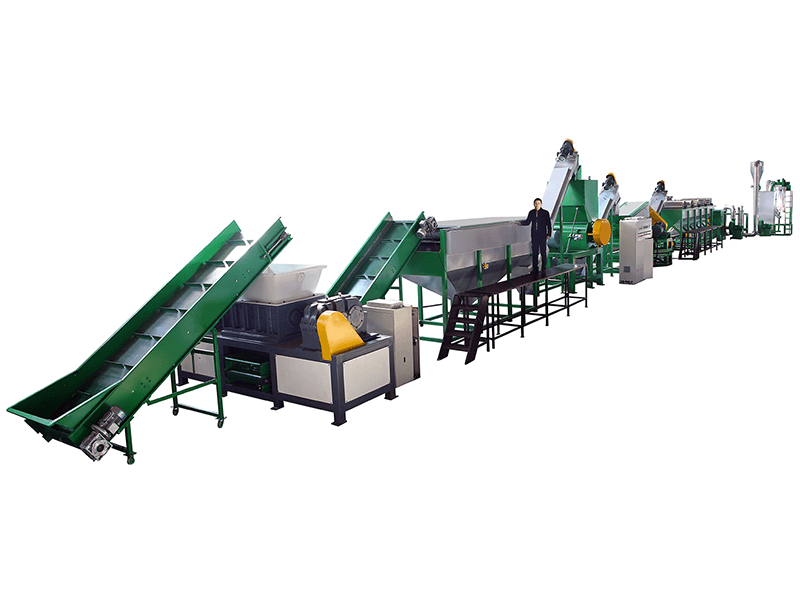

Visual Evidence: The Current Crisis

A clear indication of the urgent need for systematic recycling solutions

Current Reality

Banning plastic is not a permanent solution - it still gets sold in black markets. While administrative bans may seem like a green solution, true sustainability requires efficient recycling systems that transform waste into valuable resources.